In the automotive industry, maintaining optimal operating temperatures is crucial for engine performance, fuel efficiency, and overall reliability. As vehicles become increasingly complex and efficient, the demand for innovative cooling solutions has never been greater. Enter micro-channel heat exchangers, the cutting-edge technology revolutionizing automotive cooling systems and unleashing unprecedented levels of efficiency.

Cooling Challenges in Automotive Systems

Modern vehicles generate a significant amount of heat during operation, particularly in high-performance engines and electric vehicle (EV) battery systems. Traditional cooling systems, such as radiators and air-cooled designs, often struggle to dissipate this heat efficiently, leading to overheating, decreased performance, and potential damage to critical components. In this context, micro-channel heat exchangers offer a game-changing solution to the challenges of automotive cooling.

Compact Design, Enhanced Performance

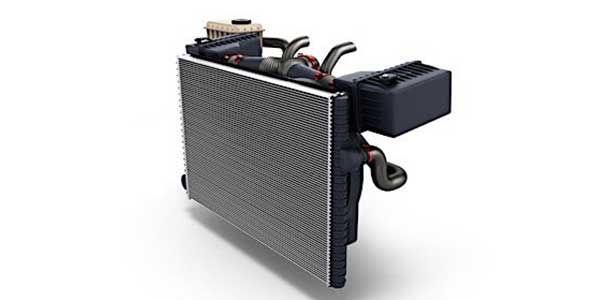

Micro-channel heat exchanger are characterized by their compact design and intricate network of small channels, which facilitate the flow of coolant or refrigerant in close proximity to heat-generating components. This design maximizes the surface area available for heat transfer, allowing for more efficient cooling in a smaller footprint compared to traditional heat exchangers. By harnessing the power of micro-channel technology, automotive cooling systems can achieve higher thermal efficiency and greater reliability.

Optimizing Thermal Management

In automotive applications, micro-channel heat exchanger are employed in various cooling systems to optimize thermal management and ensure optimal performance under diverse operating conditions. In internal combustion engines, micro-channel heat exchangers play a crucial role in cooling engine oil, transmission fluid, and intercoolers, helping to regulate temperatures and prevent overheating. In electric vehicles, where battery temperature control is critical for performance and longevity, micro-channel heat exchangers provide efficient cooling solutions that maximize driving range and reliability.

Benefits for Automotive Manufacturers

The adoption of micro-channel heat exchangers offers numerous benefits for automotive manufacturers seeking to enhance vehicle performance, efficiency, and sustainability. By replacing bulkier cooling components with compact micro-channel designs, automakers can reduce vehicle weight, improve aerodynamics, and optimize space utilization. This not only enhances vehicle performance and fuel efficiency but also contributes to overall cost savings and environmental impact reduction.

Advancements in Materials and Manufacturing

Continual advancements in materials science and manufacturing techniques are driving further innovation in micro-channel heat exchanger technology for automotive applications. Engineers are exploring new materials with enhanced thermal conductivity and corrosion resistance properties, as well as advanced manufacturing processes such as laser welding and brazing. These advancements enable the production of micro-channel heat exchangers that are lighter, more durable, and more cost-effective than ever before, paving the way for widespread adoption in the automotive industry.

Future Outlook

As automotive technology continues to evolve, the role of micro-channel heat exchangers in automotive cooling systems is poised to expand further. With their compact design, enhanced performance, and versatility, micro-channel heat exchangers offer automotive manufacturers a powerful tool for optimizing thermal management and meeting the demands of increasingly efficient and sustainable vehicles. As the automotive industry embraces innovation, micro-channel heat exchangers will undoubtedly play a key role in shaping the future of automotive cooling.